The Pros and Cons of Plastisol Printing

We get it—choosing the right ink can be tough. With all of the options out there in the custom apparel universe, it’s hard to know which one is right for your project.

Plastisol ink is by far the most popular choice for screen printing, and for good reason. This type of ink is durable, versatile, and relatively easy to use, making it a solid choice for all kinds of custom apparel projects.

So, is plastisol the move? Well, it depends on what’s most important to you. There is no such thing as the perfect ink. Each option has its benefits and drawbacks.

That’s why we’re going to go over the pros and cons of plastisol printing so you can make the right ink choice for your next screen printing project.

What is plastisol printing?

Like the name implies, plastisol printing is a type of screen printing that uses plastisol inks. These inks are made from PVC (polyvinyl chloride) and plasticizers, making them thicker and more opaque than water-based inks. Plastisol inks are the most commonly used inks for screen printing due to their versatility and ease of use.

How plastisol printing works

Plastisol inks are applied to the garment using a screen printing process. A screen is created for each color that needs to be printed. The ink is then pushed through the screen onto the garment. Once the ink has been applied, it needs to be cured (a.k.a. set) with heat in order to become permanent.

Where plastisol ink came from

Plastisol ink was first developed decades ago as an alternative to water-based inks. These inks were created to be used on non-porous surfaces like plastic and glass. However, screen printers soon discovered that plastisol inks could also be used on fabric. Plastisol inks quickly became the standard for screen printing.

The pros of plastisol printing

There’s a reason why plastisol is one of the most popular types of ink to use for screen printing. Here are a few reasons to choose plastisol ink:

Plastisol inks are versatile.

They can be printed on a variety of different fabrics, including 100% cotton and blends.

Plastisol inks are highly opaque.

One of the biggest advantages of plastisol inks is that they can be printed on any color fabric. This is because the ink is so opaque that it will completely cover up the color of the fabric underneath. They can also be printed over dark fabrics and still produce vibrant results.

You can print fine details with plastisol inks.

Plastisol inks are thick, which means they can hold onto the intricacies in your design. This makes them a great choice for printing artwork with a lot of small details.

Plastisol inks are durable.

Once cured, plastisol inks are very tough and can withstand a lot of wear and tear. You can wash plastisol-printed garments over and over again without worrying about the image fading or cracking.

Plastisol is less expensive than many other inks.

If you’re looking to save some money on your t-shirt printing, plastisol inks are a good option. It is one of the most affordable types of ink to use.

It’s easy to get an exact Pantone match with plastisol.

When you need an exact color match, plastisol inks are up to the task. You can find Pantone-matched inks that will produce results that are true to the color you need.

Many specialty inks are derived from plastisol.

If you’re looking for a particular effect, like glow-in-the-dark or metallic ink, chances are it’s made from plastisol. This is because these inks need to be very opaque and durable.

The cons of plastisol printing

Plastisol inks are not as eco-friendly as their alternatives.

Plastisol inks can be harmful to the environment if they are not disposed of properly.

Plastisol inks are not as breathable as water-based inks.

Hot weather can be uncomfortable enough without having to worry about your t-shirt sticking to your skin. If you live in a hot climate, or if you plan on doing a lot of physical activity in your plastisol-printed shirt, you might want to consider another type of ink.

Plastisol inks have a heavier hand feel.

By “hand feel,” we mean the way the ink feels on the fabric. Plastisol inks tend to have a thicker, heavier feel than water-based inks. This can be a good thing or a bad thing, depending on your preferences. Some people like the way plastisol inks feel, while others find them to be too heavy.

How to know if plastisol ink is right for your project

Now that you know the pros and cons of plastisol inks, you can decide if they’re right for your project. Here are a few factors to keep in mind:

The type of fabric you’re printing on

Plastisol inks work well on a variety of different fabrics, including 100% cotton and blends. If you’re not sure what type of fabric your shirt is made from, ask your printer or look it up online.

The color of the fabric you’re printing on

As we mentioned before, plastisol inks are highly opaque. This means they can be printed on any color fabric, including dark colors. Other types of ink are not always as versatile, but plastisol will work well regardless of the color of your garment.

The design you’re printing

Plastisol inks are thick, which means they can produce detailed designs easily. If you’re looking to print a design with a lot of small details, plastisol inks are a good choice.

The climate you (or your target customers) live in

If you live in a hot climate, or if you see your shirt enduring a lot of outdoor activity, you might want to consider another type of ink. Plastisol inks are not as breathable as water-based inks, so they might not be the most comfortable choice in these situations.

Your budget

Plastisol inks are less expensive than many other types of inks, so they’re a solid choice if you are looking for a cost-effective ink.

Your printing priorities

Everyone has priorities—in life and in screen printing.

TBH, your ink choice will come down to what matters the most to you.

If you need an exact color match, or if you’re looking to print a design with a lot of small details, you can’t go wrong with plastisol inks.

However, if you’re looking for an eco-friendly option, you might want to consider another type of ink.

Common alternatives to plastisol ink

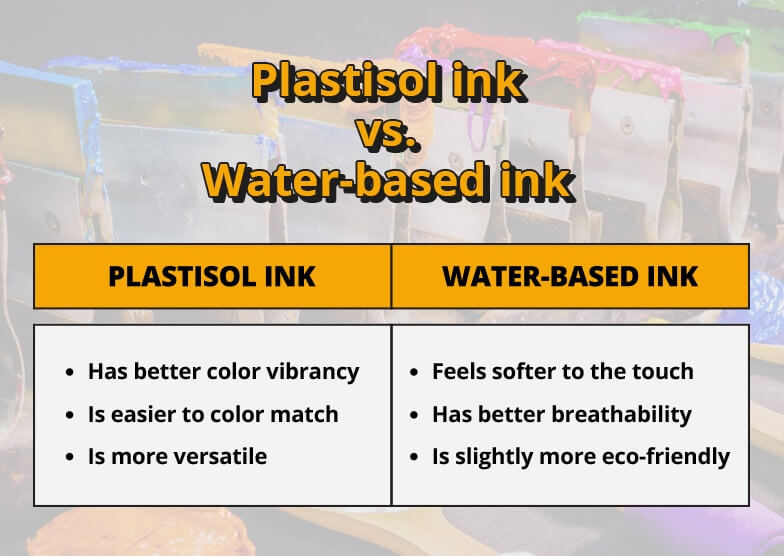

If you decide not to use plastisol ink, water-based and discharge inks are solid alternatives. Let’s look at the pros and cons of each:

The pros of water-based inks

Water-based inks are slightly more eco-friendly.

Since they do not contain PVC, they don’t have as many harsh chemicals.

Water-based inks are breathable.

They allow air to flow through the fabric, making them more comfortable to wear in warm weather. Water-based inks are also less likely to cause skin irritation.

Water-based inks have a softer hand feel.

If you’re looking for a shirt that’s soft to the touch, water-based inks are great. The ink is absorbed into the fabric, resulting in a softer feel.

The cons of water-based inks

Water-based inks are less opaque.

They are not as good at covering up dark fabrics or prints with a lot of detail. If you need a shirt that is truly opaque, water-based inks might not be the right choice.

Water-based inks can be more expensive.

It’s up to you to decide if the price tag is worth it for the benefits of water-based inks.

Pros of discharge inks

If you’re into the vintage look, discharge is the way to go.

Discharge inks produce a softer, more vintage print that has been “faded” into the fabric.

Discharge prints never crack or peel.

This printing method actually dyes the fabric, so you don’t have to worry about the image cracking or peeling over time.

Discharge inks are more eco-friendly.

Like water-based inks, they are made with water-based pigments. They are also PVC-free, which is why many eco-conscious companies choose discharge inks.

Like water-based inks, discharge inks produce a softer hand feel for each garment.

Discharge screen printing results in beautiful artwork that is soft to the touch.

Cons of discharge inks

Discharge inks can be more expensive.

For exact pricing on all of our inks, request a free quote from our team.

If you’re looking for an opaque print, discharge inks are not the way to go.

Discharge inks produce a unique vintage look for t-shirts. If you want 100% opaque colors, plastisol ink would be a better choice for your project.

No matter what type of ink you choose, make sure you work with a custom apparel partner who knows what they’re doing. With the right partner, you’ll be able to create custom apparel that looks great and lasts.

How to get the most out of your plastisol prints

If you’ve decided to use plastisol inks for your next project, there are a few actions you can take to ensure that your prints turn out the way you imagined they would:

Choose the right plastisol ink.

There are many different types of plastisol inks on the market. Make sure you choose an ink that is specifically designed for the type of garment you’re printing on. If you choose a savvy custom apparel partner, they can advise you on which ink to use for your project.

Work with an experienced screen printer.

Screen printing with plastisol inks is not as easy as it looks. Make sure you work with a partner who has experience printing with this type of ink.

If you work with an inexperienced company, you run the risk of getting poor-quality prints that crack and peel over time (and that would be a custom apparel disaster!)

Follow care instructions for your garments.

Plastisol inks are durable, but they do require some special care. For example, you should avoid ironing directly on the print. Follow the care instructions for your garments to ensure that your prints last.

Plastisol printing has its pros and cons, but it can be a great option for custom apparel. With the right partner, you can create luxury-level prints that are durable and comfortable.

Why Scrappy Apparel is the right choice for your plastisol printing project

We have over 16 years of experience printing with plastisol inks.

Our team of expert printers will work with you to manufacture garments that look phenomenal and stand the test of time.

We source only the highest-quality inks that are specifically designed for the garments we print on.

We have a strict quality control process to ensure that every garment we print meets our high standards.

We have a team of experienced screen printers who will ensure that your project turns out great.

Seriously, we’re the dream team. Plastisol printing is like the ABCs to our seasoned experts.

Our Brand Building Process (BBP) is the best in the game.

We’ll work with you from start to finish to ensure that your plastisol printing project is a success. Our stress-free process empowers you to focus on what you do best (a.k.a. creating dope apparel designs) while we do all the heavy lifting for you.

We source the best fabrics and inks for our customers, and we complete the manufacturing of each garment from start to finish.

All you have to do is request your free quote and send us your project details. We will take care of the rest!

We ship free to the USA.

You read that right.

Our passion for custom apparel shows in our work.

When you partner with Scrappy Apparel, you’re partnering with a company that cares. Every single detail matters to us, and we’ll work with you to create custom apparel that you’re proud to wear and sell.

Our orders arrive on time.

Time is of the essence, and we know you have deadlines to meet. That’s why we guarantee that your order will arrive on time (or early).

We offer free quotes that are 100% transparent. (No hidden fees!)