Water-based screen printing is one of the many choices you can make when you order custom apparel. But with many different screen printing options to choose from, how can you know which one is right for you?

Today, we’re going to share the features, benefits, and drawbacks of water-based inks and water-based screen printing. We will also touch upon water-based screen printing’s #1 enemy, plastisol. (Just kidding. They’re more like friendly competitors.)

Water-based inks are one of the most popular choices for custom apparel printing. They provide a soft hand feel and stunning colors, making them ideal for t-shirts and other garments.

Their lightweight prints are also the perfect choice for these hot summer days.

Let’s dive deeper into all things water-based screen printing.

What is Water-Based Screen Printing?

Water-based screen printing is a printing technique that uses water-based inks. These inks are thinner and more transparent than most other screen printing inks, which means they soak into the fabric. This results in a print that is much softer to the touch and less likely to crack over time.

This type of printing is becoming more popular because it is generally more environmentally friendly than PVC-based inks. Water-based inks are also thinner than PVC-based inks, so they dry faster and don’t clog screens as easily.

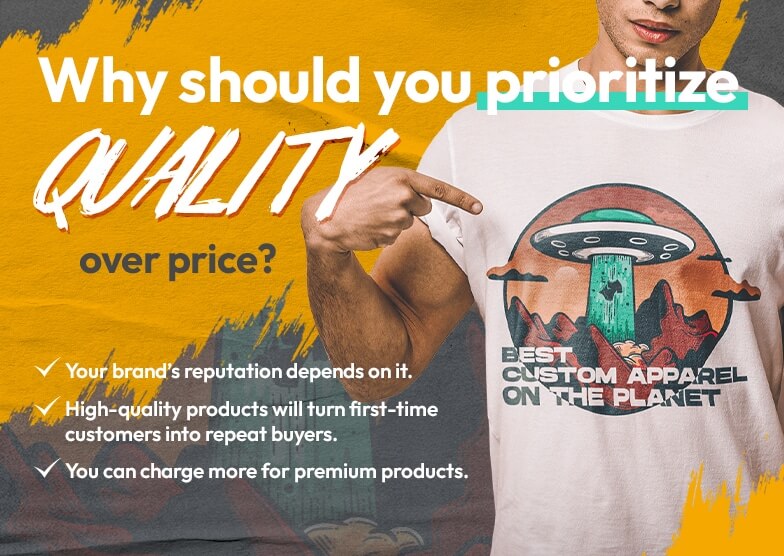

Water-based screen printing is a great way to get your message across without compromising on quality. You should never have to give up either the feel of the fabric OR the feel of the print.

At Scrappy, we’ll provide you with the best of both worlds—regardless of which printing technique and ink you choose. We’ll also be happy to advise you on what will work best for your project. We’ve been in the game for 16 years, and we’re here to help every step of the way.

For now, let’s take a closer look at the logistics of water-based screen printing:

What You Should Know About Water-Based Screen Printing

Now that we know what water-based screen printing is, let’s dive into some more information about it. Like most things in this world, this screen printing type has its own advantages and disadvantages that you will want to consider before you use it.

1. Water-Based Inks Are Lightweight and Have a Softer Hand

Water-based inks produce lightweight prints because they have a softer hand. In the custom apparel world, a hand is basically how a print feels after its printed. Water-based inks are lightweight enough to produce an almost no-hand feel on prints—so your prints will not only look fresh, they’ll feel fresh too.

2. Breathability Like Never Before

Water-based inks absorb deep into the fabric when printed, resulting in more breathability.

And believe us, you’ll want a shirt that allows moisture to travel efficiently during these hot summer days. No one wants sweat build-up in a cool-looking shirt.

3. Slightly More Environmentally Friendly When Compared to Other Inks

Water-based inks contain few volatile organic compounds (VOCs), which means they release fewer harmful chemicals into the atmosphere. This makes them better for both the environment and human health.

However, don’t get us wrong. We say they’re slightly more environmentally friendly when compared to other inks, but not all water-based inks are 100% eco-friendly, either. The specific ink you choose matters a lot. Speak with our team to learn more.

4. Water-Based Printing Dries Fairly Quickly

The ink used in water-based screen printing dries quickly, making it a great choice for high-speed production runs. Water-based inks also provide excellent color reproduction and durability.

5. Store In the Right Place

We cannot stress this enough: store your water-based printed shirts in the right place. There are a few things to keep in mind when storing your water-based screen-printed custom apparel.

- First, make sure to store it in a cool, dry place.

- Second, if possible, store it in a dark place – this will help prevent the colors from fading.

- Finally, be sure to store it away from direct sunlight, as this can also cause the colors to fade.

6. Light Colors Are the Way To Go

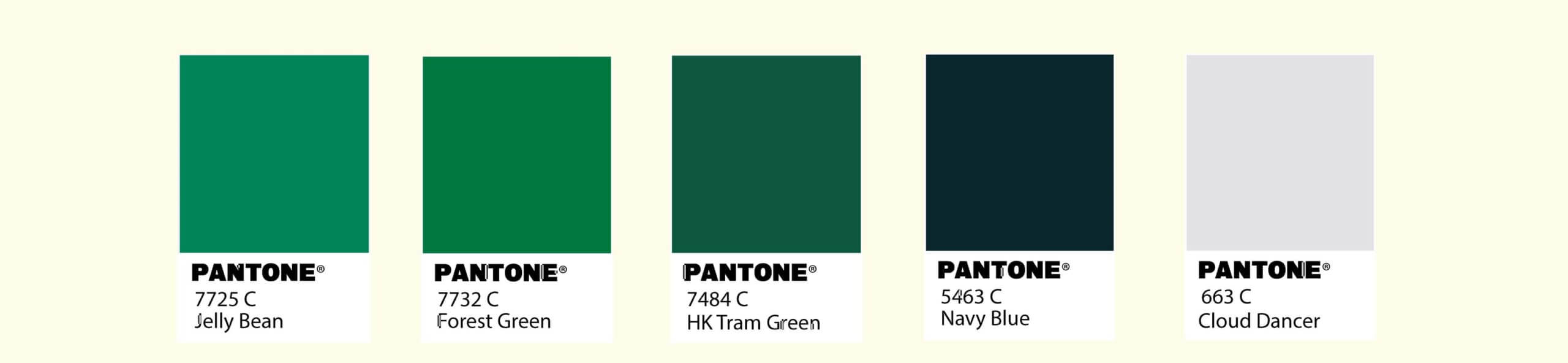

Since water-based screen printing uses dyes or pigments in a suspension of water, your best color results will appear on a lighter color base.

Imagine diluting some paint in water and trying to paint a black piece of paper. You’ll see the colors, they just won’t show as nicely as they would on a white piece of paper. Screen printing on t-shirts with water-based ink works the same way.

Of course, we always keep your best interest in mind, so we want you to know that light shirt colors are the way to go.

7. Use Discharge Ink to Print Light Colors on a Dark Shirt

If you want to use a water-based ink on a dark shirt, we recommend a process called discharge screen printing.

Discharge inks remove the dye from the shirt through a chemical reaction and then print the new design color on top of the shirt. The fabric of the shirt does not change, but the color does. This is a great way to get a vibrant design on a dark shirt without worrying about ink coverage.

The downside to discharge screen printing is that it can be a bit more expensive, and it requires a specific discharge ink. It’s also important to keep in mind that the discharge process works best on cotton. It’s not suitable for synthetic fabrics.

Discharge screen printing is a special process because it produces a print that looks like it came out of a high-end vintage store. If you’re going for that vibe, discharge screen printing is a great option for you.

8. Water-Based Inks May Not Be the Brightest Ever

As we mentioned above, the dyes and pigments are suspended in water with water-based printing. This results in colors that seep into the fabric, which in turn leads to some fabric texture coming through. We aren’t saying your prints will be dull or anything, but they probably won’t be as bright as they would be using plastisol ink.

9. Cotton Is the Way To Go

100% cotton is the best option for water-based screen printing. If you want to learn more about your fabric choices, speak with our team.

10. Water-Based Screen Printing Requires Training

Water-based screen printing takes a lot of training to perfect. And we mean A LOT.

Due to the colors reacting differently with different fabrics or maybe just not cooperating, becoming an expert in this printing style is basically a necessity before you begin doing it.

Don’t worry, you can leave this process to the screen printing experts at Scrappy Apparel. We’re here to help with your water-based screen printing needs.

What About Plastisol Inks?

Plastisol inks are a type of ink used for printing designs on garments. They are made from PVC resin and plasticizers, which gives them a thick, viscous consistency. Plastisol inks are commonly used in screen printing because they can be printed on a variety of fabrics.

Similarly to water-based inks, plastisol is widely used and is a popular ink choice for custom apparel. They’re kind of like the Batman and Superman of the custom apparel world. They each have their own superpowers, and they’re constantly compared to each other.

How Does Water-Based Screen Printing Compare to Plastisol?

Between water-based and plastisol ink, who wins? Let’s put these two inks in the octagon and watch them fight to the death. Maybe not to the death, but let’s see how they compare to one another.

Round 1: How the Print Feels

As we mentioned before, water-based screen printing leaves little to no hand behind with their prints. They’re lightweight and feel like there’s nothing even printed.

What about plastisol? Well, since plastisol is solid and thick, it does leave behind a heavier hand due to the fact that the ink sits on the fabric, unlike water-based inks that seep into it.

Round Winner: Water-Based

Round 2: How Accurate Can the Color Really Be?

It’s round two. Who will win the color accuracy test? To refresh your memory, water-based inks seep into the fabric so the color tends to vary slightly due to this.

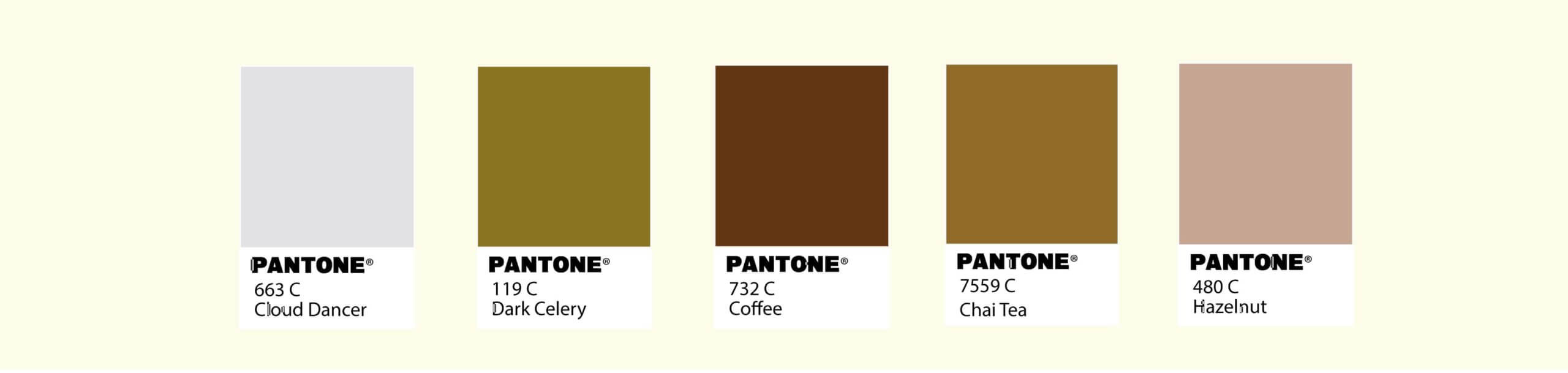

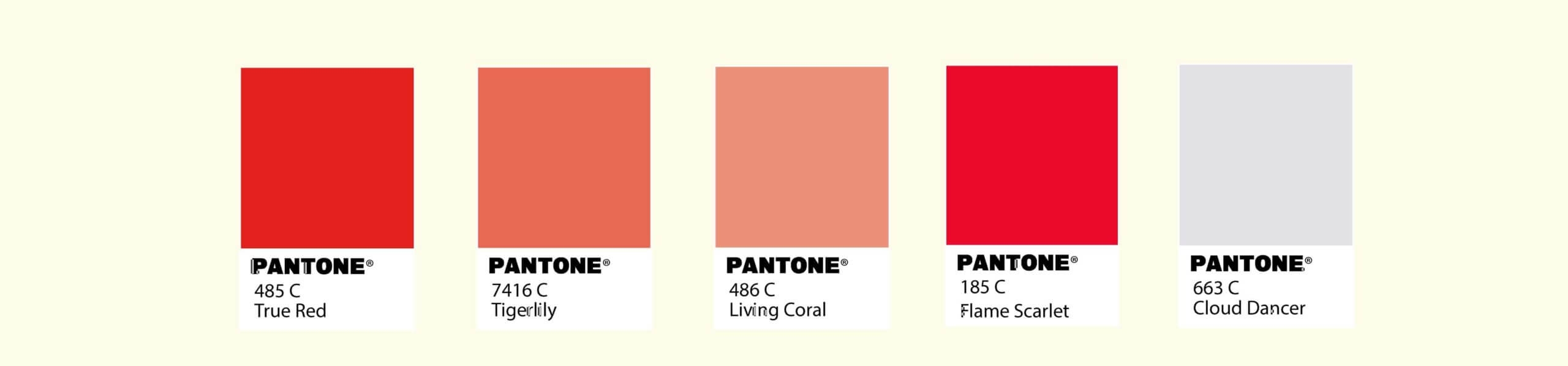

Plastisol, on the other hand, is able to accurately match any Pantone color no questions asked. To add to this, plastisol will accurately match the color on any type of fabric, while water-based inks will do best on just cotton and typically only white or light-colored cotton.

Round Winner: Plastisol

Round 3: Putting Breathability to the Test

How well does the moisture come through with these two inks? Water-based inks are lightweight and seep into the fabric, allowing a good amount of breathability.

Due to its thickness, plastisol tends to clog up the gaps between the fibers of the shirt, creating one large surface of the ink. This thick surface will create a lack of breathability that simply doesn’t compare to the lightweight feel of a water-based print.

Round Winner: Water-Based

Round 4: Vibrancy of Colors of the Print

We talked about accuracy. Now, let’s battle vibrancy.

Water-based inks are suspended in water, leading to colors that are bright, but not the brightest.

They also seep into the fabric, creating a tiny bit of vibrancy loss. Plastisol, on the other hand, will create vibrant hues on any fabric color.

While water-based colors do a great job of being vibrant on white or light-colored shirts, plastisol just does vibrancy better all around.

Round Winner: Plastisol

Round 5: How Versatile Can They Be?

Versatility is an important factor when choosing a type of ink. As we said, water-based screen printing performs best on 100% cotton, On top of that, the cotton must be either white or light-colored for the inks to show up well.

Plastisol can succeed on a variety of different fabrics, though. 100% cotton or blended textiles are great choices for plastisol inks. Plus, they succeed on any color fabric. Plastisol brings all the fun.

Winner: Plastisol

Round 6: Earth Friendly Inks

This one is a bit of a complicated round to win. Although we did say that water-based screen printing is the better, more eco-friendly choice, it isn’t a completely harm-free option.

While water-based inks contain some harmful ingredients, plastisol inks just happen to contain more. So, even though it’s only by a tiny bit, water-based inks are the more eco-friendly choice.

Winner: Water-based

Water-Based Screen Printing or Screen Printing With Plastisol Ink?

It’s about a fair match between these two well-known inks. We can happily declare a tie in this battle because they’re both winners. As a custom apparel company, we enjoy working with both of these inks.

Honestly, both do great work. It all depends on the results you’re going for. If you’re looking for something airy and lightweight, choose water-based screen printing in your next custom apparel order. This is a great option for a company that works outdoors (Ex. a roof repair company) that requires shirts to allow moisture to travel.

If you want complete vibrancy and accurate colors, we recommend plastisol. This is the perfect choice if your company logo has a lot of colors that need to be directly matched onto the print.

Why Choose Scrappy Apparel for Your Water-Based Screen Printing Project?

Here are some rapid-fire facts about why Scrappy Apparel is the best choice:

1. We are a 100% online solution for your custom apparel needs.

No more trips back and forth from your local print shop. We’ll ship your order right to your doorstep.

2. We offer free shipping on all orders.

You mean the world to us, so consider the shipping free.

3. Our turnaround is quick, and we always deliver orders on time.

We have some of the speediest turnaround times in the industry, and we are committed to delivering on our promises. Deadlines are just as important to us as they are to you.

4. We offer a wide range of services, including multiple printing techniques and private labeling.

We’re a one-stop shop for all your custom apparel needs. We offer screen printing, sublimation, custom embroidery, and more. We can also help you with private labeling and other branding needs.

5. We’re always happy to answer any questions you may have about our products or services.

We’re here to help! Our team is available to answer all your burning Qs.

If we can give you one choice without any competition, it’s us. Scrappy Apparel will be the best custom apparel company you’ll ever work with and not only do we say it, but all of our customers say it, too.