Real talk: We only get one Earth.

As a custom apparel manufacturer, we are conscious of how our production choices affect the environment.

That’s why we feel it’s important to educate our customers on which inks, materials, printing techniques, and processes are the kindest to this planet we call home.

We do our best to reduce our footprint, but we also strive to offer our customers as many options as possible. For customers who want to make their projects more eco-friendly, we offer water-based inks, polybags made from recycled material, and sustainable fabrics.

As an educated customer, it’s up to you to decide what’s right for your brand—and today we’re going to share the most eco-friendly custom apparel choices you can make.

Before we dive in, let’s take a look at the overall impact of the fashion industry on our environment so you can see the big picture:

The effects of t-shirt manufacturing on the environment

Without sustainable manufacturing practices, the process of making a t-shirt can have a significant impact on our ecosystem. Fashion is one of the most polluting industries in the world, and the mass production of fast fashion is a major contributor to this pollution.

The farming of conventional cotton uses a lot of water and chemicals, which can pollute our air and water. (However, there are more sustainable alternatives. We’ll talk more about that in a sec.)

The manufacturing process itself can also use a lot of water and energy. Inks that use unsafe dyes and other chemicals can pollute the water that’s released back into the environment.

But don’t let these effects discourage you from creating your own custom apparel. There are more eco-friendly ways to print t-shirts, so keep reading to learn how!

Why eco-friendly t-shirt printing is the move

Of course, it’s important to protect the environment because we live in it—but there are other practical reasons to consider eco-friendly t-shirt printing.

Sustainable practices can save you money in the long run. Using less water and energy reduces your production costs. And if you use biodegradable materials, you may be able to avoid the cost of future environmental cleanup.

In addition, eco-friendly t-shirt printing can help you build a positive brand image. Increasingly, consumers are looking for brands that share their values. By marketing your eco-friendly t-shirt printing, you can position your brand as socially and environmentally responsible.

Now that we’ve covered the basics, let’s get into the good stuff. Here are five tips to make your custom apparel brand more eco-friendly:

1. Use water-based inks.

You might be wondering what makes water-based inks more eco-friendly than plastisol inks. Well, for starters, water-based inks are made without PVCs or phthalates, which can be harmful to both the environment and your health.

Water-based inks are also much easier to clean up. They don’t require the use of harsh chemicals in order to be removed from screens.

BTW, our water-based inks are non-toxic. They are free of lead and other hazardous metals, and they do not contain any ozone-depleting chemicals or volatile solvents.

Our water-based inks are better for the environment than plastisol alternatives, and they give your designs a soft hand feel. (It’s a win-win.)

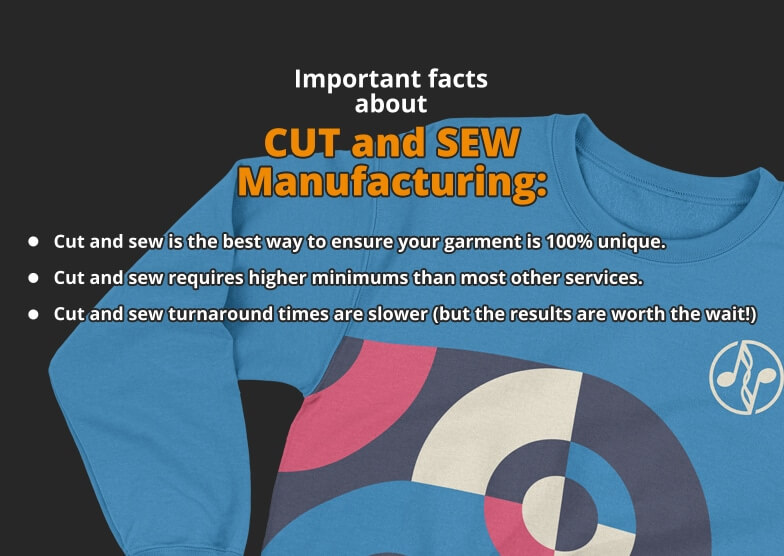

2. Choose an eco-friendly printing technique.

Screen printing is a durable printing method that supports the use of sustainable inks, and it results in very little waste.

The longevity of each garment makes screen printed products more eco-friendly. (Think about all of the water and energy that is saved when you don’t have to replace your clothing as often!)

Additionally, screen printing is one of the most versatile printing methods available—it can be used on a variety of different fabrics, including eco-friendly materials like organic cotton.

You can’t go wrong with screen printing. Just mention to our team that you want your custom apparel project to be more eco-friendly, and we will advise you on the best choices to make.

3. Use eco-friendly materials.

We source a variety of fabrics for our customers, and some are more sustainable than others.

The use of eco-friendly materials helps to reduce the number of chemicals that are released into the environment.

For example:

Organic cotton

Organic cotton is grown without the use of pesticides or other harmful chemicals, which makes it a safe choice for both the environment and the people who work in the cotton industry.

However, there is a major difference between chemically grown cotton vs. organic cotton.

Organic cotton is a more sustainable choice because it requires less water and energy to produce. In fact, organic cotton can grow from rainfall alone—no irrigation required!

Additionally, organic cotton benefits the environment in other ways. For example, it helps to improve soil health and preserve biodiversity.

Eco-Hybrid fabric

Our Eco-Hybrid t-shirts are made with a blend of 50% Lenzing Modal and 50% Combed Cotton. These are more environmentally friendly than garments that are 100% synthetic.

The Eco-Hybrid threads we offer are sustainable, biodegradable, and 100% natural. The use of eco-friendly materials helps to reduce the impact that t-shirt manufacturing has on the environment.

4. Use sustainable packaging.

Since plastic contributes to pollution, it’s important to consider the packaging of your t-shirts if you want to be more eco-friendly.

We offer free folding and polybagging for all our customers. When your t-shirts arrive on your doorstep, they will come in polybags that are made from recycled materials.

5. Consider the end of life for your garments.

In a perfect world, we could wear our t-shirts forever. But in reality, t-shirts (and other garments) eventually wear out.

When that time comes, it’s important to consider the end of life for your eco-friendly t-shirt. Educate your customers and employees on what to do with their garments to ensure they don’t end up in landfills.

Here are a few ways to give old t-shirts new lives:

1. Recycle the garment

You can recycle eco-friendly t-shirts by sending them to a textile recycling facility.

2. Upcycle the garment

If the artwork on the t-shirt is still in good condition, you can upcycle it into something new, like a tote bag or a pillowcase.

3. Donate the garment

If the t-shirt is still wearable, you can donate it to a local thrift store or charity.

Let us advise you on the most environmentally conscious choices for your custom apparel project.

At Scrappy Apparel, we offer water-based inks and a variety of eco-friendly materials, like organic cotton and Eco-Hybrid fabrics.

We are a fully transparent custom apparel partner. Our team will be happy to answer your questions about how you can make your t-shirt printing process more eco-friendly. Ready to get started?