Decoding Inks: Find the Perfect Match for Your Screen Printing Project

At first, “screen printing” might sound like a simple process—but the reality is that there’s a world of creativity and possibilities at your fingertips.

When you produce a garment for your brand or organization, the choices you make during the manufacturing process will affect the finished product (probably more than you realize!)

Choosing the right ink is one of the most critical decisions you’ll make.

It will affect:

- The vibrancy of your print

- The longevity of the garment

- How the garment feels—and whether or not it’s comfortable to wear

With the right ink, you can add a touch of magic to your designs. But each ink comes with its own pros and cons.

We wrote this guide to help you. Today, we’ll cover the most commonly used inks in screen printing, their use cases, and the pros and cons you should consider.

You’ll want to take notes—this decision could make or break your next screen printing project!

Work with Scrappy’s Team to Make the Best Choices for Your Project!

Why Does Ink Matter?

We already mentioned a few technical reasons, but let’s dive deeper.

Aside from the garment itself, your ink choice will help communicate your brand’s message with quality and integrity.

How would you feel if you bought a t-shirt from your favorite brand and the print started cracking and peeling after the second wash?

At best, you’d be annoyed. At worst, you’d demand a refund and never order from that brand again.

Don’t let a poor ink choice ruin an otherwise stellar garment. Your brand reputation depends on it.

Choosing the wrong ink can also lead to material waste and financial losses. For example, if the ink doesn’t adhere well to the fabric or requires additional manufacturing processes, you’ll end up spending more than necessary.

Now, imagine if you need to produce thousands of garments. Even a seemingly small increase in the cost per garment can multiply your overall costs significantly.

Exploring Screen Printing Inks: An Analysis of the Most Common Options

Now that you see the big picture, let’s break down the most common types of screen printing inks—plastisol, glow-in-the-dark, and everything in between!

Plastisol Ink

First, let’s discuss the most commonly used ink in screen printing—plastisol.

It’s a top choice due to its durability, versatility, and user-friendly nature. It works well across a wide array of garments and screen printing projects.

Plastisol inks are composed of PVC (polyvinyl chloride) and plasticizers. They boast a thicker consistency and greater opacity compared to water-based alternatives.

However, eco-conscious brands and consumers often criticize plastisol ink because it leaves a much larger footprint than water-based alternatives.

Pros

- It’s highly versatile and can be printed on a wide variety of fabrics.

- Its opacity allows you to cover any color fabric with ease.

- It’s highly durable and can withstand a lot of wear and tear.

- It can replicate any Pantone color with ease.

- It’s cheaper than many other inks.

Cons

- It requires specialized equipment for proper heat curing.

- It’s not as breathable as other inks.

- It may feel heavier as it tends to be thicker.

- It may crack if stretched excessively.

Water-Based Ink

Water-based inks are fan favorites for eco-friendly brands. They utilize water as the primary solvent instead of harsh chemicals.

Water-based ink permeates the fabric more deeply than plastisol. It offers a softer print that’s more integrated into the fabric, making it a great choice for a comfortable, natural feel.

Pros

- It’s more environmentally friendly.

- It’s easy to clean up and less likely to clog screens.

- It’s vibrant, yet soft and breathable, resulting in a comfortable feel.

Cons

- The printing process requires meticulous maintenance and temperature control, which may incur additional costs.

- Its quick-drying properties make it harder to work with.

- It’s less opaque when applied to darker fabrics, so your fabric choices are limited to light colors.

Discharge Ink

Discharge ink is a type of water-based ink that includes an activator. When added to the ink, the activator initiates a process where the dyes from the garment are removed.

The process results in an off-white or bleached appearance, similar to a natural canvas if color pigments aren’t introduced.

If you want to use water-based ink on a dark fabric color, discharge ink is the way to go.

Pros

- It provides a vintage, aged aesthetic to the print.

- It can be used on dark garments.

- It enables the creation of a subtle tone-to-tone effect.

- It’s easy to print on folds, seams, pockets, and other challenging areas.

Cons

- It’s best suited for use on 100% cotton garments.

- If you don’t have an expert partner, you may have inconsistent results due to differences in fabric dye and color.

Reflective Ink

Now, let’s talk about specialty screen printing inks. These inks are designed to “WOW” your customers with unique elements that are not possible with traditional screen printing inks.

Reflective ink is the first we’ll discuss.

Infused with reflective materials, this ink brings garments to life in low-light conditions, perfect for sportswear and eye-catching fashion.

When exposed to light, such as headlights or ambient lighting, the reflective particles infused in the ink create a luminous effect that enhances visibility.

Pros

- It ages well, withstands wear, and survives many washes.

- It improves visibility in low-light environments, making it ideal for cyclists and outdoor enthusiasts.

- It adds a visually striking element to designs, whether incorporated subtly as accents or used boldly for entire graphics.

- It can be easily combined with other ink types and printing techniques.

Cons

- It tends to be more expensive than traditional screen printing inks.

- It’s available in a limited range of colors, often restricted to metallic silver or gray tones.

- It calls for specialized equipment, expertise, and meticulous attention to detail when used.

- The printed area may exhibit a slightly raised or textured surface compared to standard prints.

@hafsiaofficial Unisex Reflective LIGHTNING hoodie 2.0 ⚡️⚡️⚡️ Colors: WHITE / BLACK Size : XS/S/M/L/XL DM to order 📩 #hoodies #fashion #oversizedhoodie #unisexfashion #newtrend #mode #lightening #reflective ♬ son original – Hafsia

See an example of reflective ink in action!

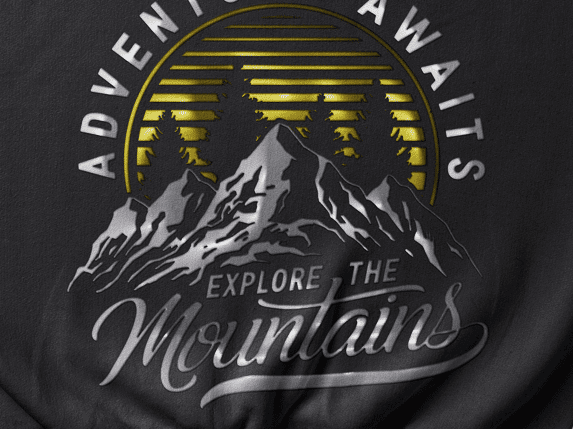

Metallic Ink

Metallic ink adds a glossy, luxurious finish to your designs. This ink contains metallic particles distributed throughout the liquid. It’ll make every garment shine—no doubt!

If you use metallic ink, we recommend selecting artwork with simplified details. Achieving intricate details can be challenging.

Why? Because the printing process utilizes a low mesh screen, which is essential for depositing the ink in a sufficiently thick layer to achieve the desired metallic effect.

Pros

- It’s remarkably durable. It ensures longevity even when garments endure regular wear and tear.

- It’s visually intriguing.

Cons

- It’s not suitable for fine details due to the thickness of the ink.

- It tends to be more expensive than other types of ink.

- It also has a limited color selection. It cannot be mixed with other inks without diluting the metallic flake.

Puff Ink

Create a 3D effect with puff ink, ideal for bold logos and text that you want to stand out.

This unique ink contains a blowing agent that expands when exposed to heat, resulting in a three-dimensional effect when heated during the curing process.

Pros

- It looks 3D and also has a unique raised feel that can give your garment a premium touch.

- It works well on a wide range of fabrics, including cotton and blends.

- It’s also flexible color-wise. You can use it for multicolored designs, halftones, or solid colors.

Cons

- It’s not well-suited for intricate designs, as it blurs out fine detailed work.

- It requires additional time and resources for exact color matching.

- It has a longer production time and may require adjustments to printing equipment and processes.

Glow-in-the-Dark Ink

This playful ink stays true to its name. It stores light to create glowing effects in the dark, perfect for designs that aim to stand out.

It’s ideal for use in low-light environments—like raves, nighttime school events, cosmic bowling… you get the idea.

Pros

- It provides an eye-catching effect that can add an extra dimension to designs.

- It offers designers the opportunity to create imaginative and innovative artwork.

- It provides a fun and engaging experience for wearers.

Cons

- It relies on exposure to light sources to recharge the ink’s luminescence.

- It typically produces a green or bluish glow, which may restrict color choices for apparel designs.

- It requires careful handling and storage to preserve the glow effect.

Still Unsure? Leverage Scrappy Apparel’s Manufacturing Expertise to Bring Your Apparel to Life!

At Scrappy Apparel, we believe in the transformative power of the perfect ink. For us, quality is non-negotiable.

We’ve been in business for over 17 years. We’re manufacturing experts and true partners who will help you select the right materials, ink, and printing process for your garment. You can count on us to keep efficiency in mind every step of the way.

Our team at Scrappy Apparel understands that manufacturing is only one step in the supply chain.

We’ve honed our manufacturing expertise since the beginning, but over the years we expanded our services to streamline every aspect of the apparel supply chain, including:

- Sourcing materials

- Manufacturing garments

- Fulfillment

- E-commerce

…and much more!

Our proprietary 3PL MGMT program transcends traditional logistics management to offer a comprehensive, end-to-end supply chain solution tailored to the unique needs of apparel brands.

Our proprietary 3PL MGMT program transcends traditional logistics management to offer a comprehensive, end-to-end supply chain solution tailored to the unique needs of apparel brands.

With an emphasis on efficiency and quality, our program integrates advanced 4PL and 5PL capabilities. We oversee every aspect of the supply chain, from the first sale to the final delivery.

So, this means you can trust us to run your backend operations while you focus on designing, marketing, and selling.

Work with Scrappy Apparel to Elevate Your Brand with Luxury-Level Garments and Seamless Logistics