By now, you must have heard of screen printing, silk printing, or serigraphy on T-shirts. Well, all of them refer to the same thing, which is based on the ancient form of stenciling art on different surfaces.

A popular belief is that screen printing came about during the 4th century in India, East Asia, and ancient Egypt. But it wasn’t until the 18th century that it gained popularity in Europe when the import of silk mesh from the East began.

The Printers ‘Nation Environment Assistance Center declares it as a highly versatile and adaptable printing technique. Today, it has become the core of various printing procedures to create aesthetically appealing and alluring pieces.

The Beginning of Screen Printing

The process, in its earliest form, was used to decorate fabrics, walls and other materials. By the 19th century, it became a common technique in the field of advertising and marketing. Andy Warhol was the first person who made it popular in 1962 when he created “Marylin Diptych”to promote Marylin Monroe.

After that, there was no turning back.

It became a significantly popular marketing tool as movie posters, album covers, and flyers were created. Screen printing was also used for devising commercial fonts and artworks, but its popularity rose in the 1960s with T-shirt printing.

The process was quite simple, using an organdy fabric on wooden frames to hold stencils. However, in the early 20th century, the process was mechanized for commercial posters, packages, and fabric printing. It also bridged the gap between handwork and automated printing, which were highly expensive.

The mass production of screen-printed materials, especially in the US, opened doors to new printing techniques and advertising strategies. Today, the process has advanced with innovative printing materials and unconventional ink types combined with the latest technologies. Today, it can be printed on any surface such as paper, wood, glass, plastic, leather, and fabric.

What is Screen Printing?

Screen printing, also called serigraphy, creates an image on paper, fabric or any other material. It stamps ink on a surface using a screen while the stencil blocks the remaining area. The method can be used for aesthetic pieces or commercial production on mugs and t-shirts.

You can create bold canvases, posters and artworks using vibrant designs with bulk production done manually.

How Screen Printing Works?

Ink + Screen (mesh stencil) result in screen printing. The mesh stretches over a frame while a negative of the design is on the screen. Then, ink rolls over, which allows the ink to slip through the gap and imprints the design on the t-shirt.

However, the process is much more complicated than explained above as it utilizes different chemicals, inks, and techniques. Here is a step-by-step guide to the basic process of screen printing:

Step 1: Finalizing the Design

Print out the design on a acetate-based transparent sheet that will be used for creating a stencil

Step 2: Preparing the Screen

Now use a mesh screen and cover it with a light-reactive emulsion because it hardens under a bright light.

Step 3: Creating Emulsion

The stencil is then placed on the mesh and exposed to bright light. However, you’ll require multiple acetate screens if the final design is multi-colored.

Step 4: Craft the Stencil

After the emulsion is hardened, the rest of the liquid is washed off. It develops a clear negative imprint of the design that allows the ink to pass through.

Step 5: Preparing the Screen Board

The material (t-shirt, paper) is placed under the screen to paint the color. It can be hand-pressed or done through automatic processes for commercial use. You can also use a rotary carousel for multicolored prints.

Step 6: Creating the Last Finish

The printed product goes through a dryer to cure the ink.This step creates a color fast and smooth finish. It is then washed to remove the entire residue and check for quality assurance before sending it to the owner.

The Various Methods of Screen Printing

Screen printing has been around for a long time.Inventors and entrepreneurs crafted new methods to provide different qualities, amount, speed and appearance. Here, we have listed down a few methods:

- Rotary Printing:

It surges the manufacturing process and increases the amount of production. However, it is commonly used for multi-colored printing. - Stencil

Throughout history, designs were either hand-painted, hand-drawn, photocopied, or printed. Stenciling was an innovative way to imprint art on different materials. - Digital Hybrid

As The name suggests, a digital hybrid joins an automatic screen printing press with a CMYK digital enhancement. It is a combination of screen printing and traditional digital direct to garment printing.

What Are The Benefits Of Screen Printing?

Newer and Vibrant Designs

When it comes to screen printing, a wide range of practices allows you to enjoy thousands of bright colors. Direct to garment (DTG) rely on thinner inks such as black, yellow, magenta, and cyan. On the other hand, CMYK dots to recreate whatever image you desire.

However, these results are comparatively dull than screen printed ones. With screen printing, you get vibrant and catchy colors.

Get Custom Results

One of the best things about screen printing is that you can get whatever you want! By manipulating the screen printing process, you can get exactly the color, texture, and shading you desire!

Efficient and Fast!

If you haven’t already caught it, screen painting is super efficient and time-saving. All you have to do is recreate the picture on the screen. Once that’s out of the way, it takes mere seconds before your T-shirt is looking like your dream come true.

A Wide Range

When it comes to screen printing, people often think their old cotton shirt is the only thing that’ll work for the process. We’re here to tell you’re wrong. Really wrong!

Not only can you get it on synthetic fabrics like polyester, silk, viscose, and many more, but you can get them on a variety of clothing types.

Long-lasting Prints

The inks’ natural composition means all the designs fabricated stand stress far more than other prints would be able. You can count on the colors to not fade until you’re fifty.

Super Versatile and Straight forward

Even if you’re part of the art world, finding a printing method is half as versatile as screen printing is, no easy task.

You can perform screen printing on almost every fabric, plastic, wood, and even metal! Given said surface is flat.

Why Choose Scrappy Apparel

Now that you know everything about screen printing, we bet you want to get your hands on some good old catchy designs, right? Wondering where you can get high-quality screen printed fabrics from? Maybe you want to get your favorite TV character printed on your soft blue shirt?

Well, what are you still surfing the net for? We’ve got just the solution for you! Scrappy is your go-to screen printing company. With their top-notch screen printing techniques fabricating wonderful patterns, there’s no way you won’t instantly fall in love!

But I can hear you asking: why should I choose them? There are so many options. Well, allow us to enlighten you!

Specialized Services

At Scrappy, we specifically work in waist-up fashion apparels including, T-shirts, zippered hoodies, sweat shirts, hats and face-masks. Instead of being a jack of all trades, we hold specialty in a limited number of embellishment techniques, such as Retail Ready Screen Printing, All Over Sublimation Printing, All Over Screen Printing and Corporate Embroidery.

Being specialists, we ensure our clients get the best and highly professional services in the select field, thus ensuring quality and perfection!

Diverse Range

Who doesn’t love having matching clothes? Want your T-shirt to have the same print as your zipped hoodie? Then this is just the place for you!

Here at Scrappy, we perform screen printing on all kinds of apparel! All you have to do is choose the print, the clothing, and then let us do our magic!

State-Of-The-Art Techniques

Cheap printing techniques, and ink often lead to your shirt fading quickly and looking pale.

To ensure your shirts keep looking bright and colorful despite daily use, Scrappy uses first-rate techniques and consistent ink. Add that to the workers’ experience and dexterity, and you’ve got yourself enthralling quality shirts!

Catchy Designs

Just because a shirt feels soft doesn’t mean it looks good. If the design doesn’t catch your eye, chances are you won’t spare it a second glance.

Here at Scrappy, we provide you with a color wheel. Choose whichever color you like best with whichever design captivates you!

Time-Efficient And Cost-Effective

What’s better than one expensive yet amazing shirt? A couple of shirts in less time for a reasonable price!

No need to waste your time on and money on clothes that take a week to reach your doorstep, and stop looking good in a couple of days. Instead, you can look through our website and choose multiple shirts without the fear of spending half your paycheck.

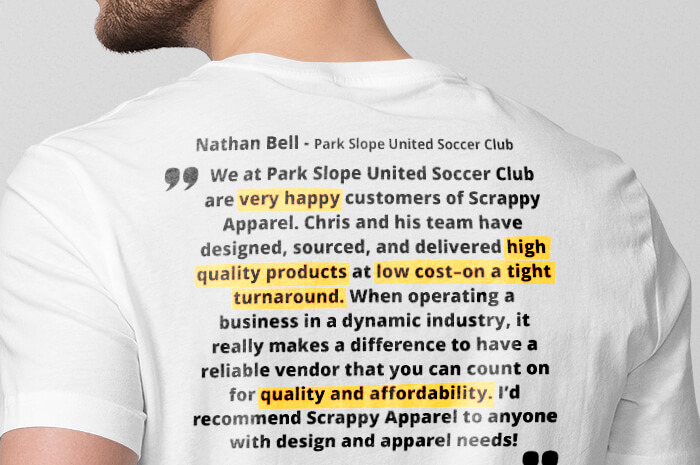

Customer’s Satisfaction

The customer’s happiness is our foremost concern. That’s why we make no compromises when it comes to quality, quantity, and integrity.

So, what are you still scrolling for? It’s time to get your hands some awesome, printed shirts!